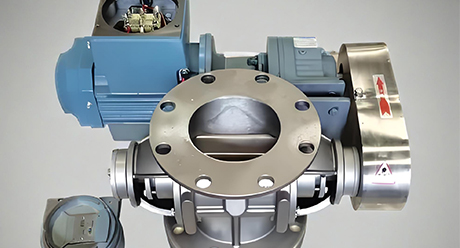

Rotary Air Valve

Rotary air-tight valves play a vital role in many industrial processes, ensuring a smooth gas flow and the metering of bulk materials from one tank or chamber to another. To minimize leaks, high-quality sealing solutions are needed. BROW rotary shaft seals are designed to meet these needs, providing superior performance, reducing maintenance costs and extending equipment life.

Rotary air-lock valve sealing

BROW rotary shaft seals are designed to replace cord seals on rotating airlocks and require no maintenance due to their self-adjusting design. Custom seal housings are available in aluminum and stainless steel, and the seals can be rebuilt using inexpensive repair kits.

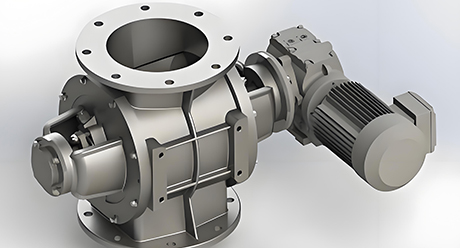

how they operate

For straight-through valves, the outlet and inlet are arranged vertically and the size is often the same. The metal blades (also called blades) of rotary air-tight valves will rotate during operation. As this happened, pockets began to appear between them. The material being processed will then enter the pockets in the inlet port before rotating, inside the valve, and exit through the outlet port.

With the air-lock valve, air will be sealed between the outlet and inlet. Because the airflow is restricted, the material inside will flow downward (through the valve) from the inlet to the outlet. In this way, the material can move continuously in the air between the two ports. Maintain vacuum or pressure differential in the valve for normal operation.

Design of rotary airtight valve

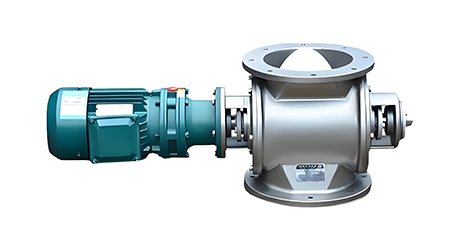

When transporting materials from A to B (compared to other systems), pneumatic conveying systems happen to be a more economical and practical method. Whether it's traction conveyors, vibrating conveyors, screw conveyors, belt conveyors or other material movement methods, pneumatic conveying systems stand out from the competition.

Related Products

English

English